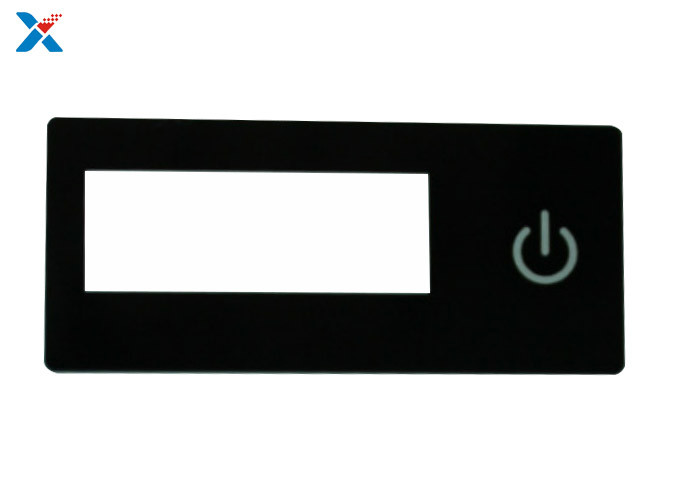

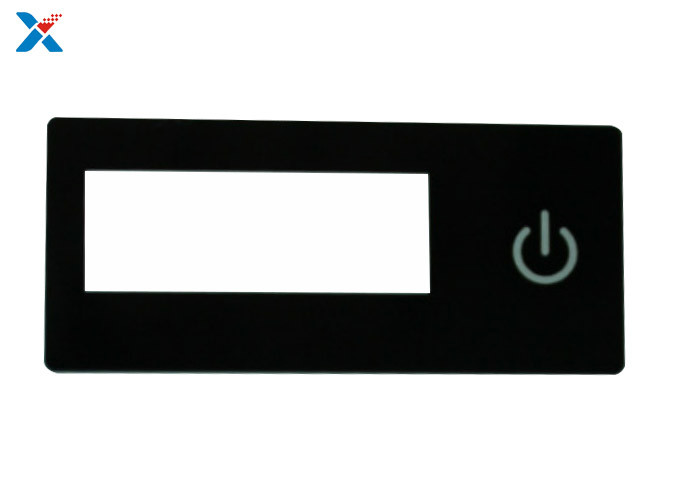

Transparent Scratch Resistant Acrylic Sheet UV Hard Coated Plexi

Glass

Transparent scratch resistant acrylic sheet UV hard coated proof

plexi glass sheet

1. Hard Coat Acrylic Sheet Description

Acrylic (PMMA) is a type of plexiglass. Acrylic mirrors made of

acrylic have a mirror effect similar to that of glass mirrors,

stronger impact resistance than glass mirrors, and only half the

weight of glass mirrors. The mirror once became the darling of the

decorative building materials industry, known as the "Queen of

Plastics".

However, acrylic is always plastic, and its hardness is far less

than that of glass, so acrylic mirrors need extra care in daily

use, because it is easy to scratch. In order to solve this problem,

the surface of the acrylic mirror needs to undergo special

treatment, which is also called "acrylic surface hardening

technology" in our industry.

1. Surface coating hardness modification

Surface coating hardness modification is known as hardcoating. It

is to coat a layer of material with high hardness on the surface of

the acrylic sheet to improve the hardness of the surface of the

sheet. The materials that can be coated are usually inorganic

substances, silicone coatings, fluorocarbon paints, multifunctional

acrylates and a small amount of thermosetting resins. The surface

coating is divided into physical coating and chemical coating

according to the nature of the combination. The combination of

physical coating and sheet only utilizes the van der Waals force

between the film and the sheet, while the molecules in the chemical

coating can interact with the side chains of the sheet. The

cross-linking of the functional groups produces a stronger chemical

bond, so the adhesion of the chemical coating is higher and more

reliable.

2. Surface coating treatment

Surface coating treatment (generally done by PVD method); mainly by

PVD method, metal, metal oxide or other inorganic substances are

coated on the surface of the acrylic mirror sheet.

PVD is the abbreviation of English Physical Vapor Deposition. It

refers to the use of low-voltage, high-current arc discharge

technology under vacuum conditions, using gas discharge to

evaporate the target and ionize the evaporated material and gas,

using the acceleration of the electric field. , so that the

evaporated substances and their reaction products are deposited on

the workpiece. The films prepared after PVD have the advantages of

high hardness, low friction coefficient, good wear resistance and

chemical stability.

2.Parameter

| Item | Place of Origin | Guangdong China |

| Brand Name | XH (Acrylic sheet manufacturer) |

| Model Number | H-001 |

| Material | High quality Virgin MMA raw material |

| Specification | Thickness | 2mm-50mm |

| Acrylic sheet Size | 2440x1220mm, 1220*1830mm, customized |

| Density | 1.2g/cm3 |

| Appearance | Color | Clear / Black / White / Blue / Red or customized |

| Light Transmission | >92.8% |

| Surface | Double Polished |

| Process Available | Processing Type | Cast |

| Process Service | Custom Cut to Size,laser dot,UV printing |

| Sample | Sample fee | Normal A4 size is free, just shipping fee |

| Sample Time | Normal size, 2days |

| Customized sample | Fee and time will be discussed by both |

| Supply Capacity | Production Ability | 50000 Pieces per Month |

| Stock | Regular size stock is sufficient |

| Lead time | 7-10 days after your order |

| Package | Acrylic sheet | Covered by PE film or craft paper on double sides |

| Package | Wooden pallet |

| Package size | 2450mm*1250mm*700mm or customized |

| Package weight | About 2000kg per pallet or customized |

| Trading Terms | MOQ | 50 Pieces |

| Main Market | All over the world |

| Shipping Port | Shenzhen/Guangzhou Port by Sea |

| Transportation | By sea/ Air/ Express/Railway |

| Trading Terms | FOB, EXW, CIF, CNF, FCA |

| Payment Terms | T/T,Western Union, Paypal |

| Using Tips | Storage | Far away from organic solvents |

| Scratching | Sharp objects may scratch the surface |

| Temperature | Long time less than 85℃ |

| Cleaning | Clean with soft cloth or scrub with soap |

3. Features:

1. Light transmittance, no impurities, anti-scratch, thickness

0.5/0.65/0.8/1.0/1.2/1.5/2.0/3.0mm, hardness 4~6H, light

transmittance above 93%.

2. Excellent transparency, excellent light conductivity, excellent

surface quality and tolerance control.

3. The high-quality protective film is used for the board

interview, and there will be no residual glue phenomenon.

4. The crystal point is controlled at the optical grade

specification.

4. Application of Hard coated Acrylic Sheet coating technology on mobile phone backplane

For decoration: such as many shop windows, lighting covers,

soundproof doors and windows, elevator interior veneers, etc.

For advertising: common light boxes, outdoor billboards, station

advertisements, indoor advertisements, fan support boards and

signs, etc.

For children: driving safety seat mirrors, children's furniture,

children's toys, etc.

Used for other: baby's incubator, medical device, fluorescent lamp,

chandelier, lampshade, etc.

5. XH Company and Production Line

7. Package and shipping

7.1. One piece of acrylic sheet package: double-sided covered with

kraft paper or PE film, the cover film does not have any LOGO of

our company.

7.2. Tray package: the total weight of each pallet is about 2 tons,

the bottom is wooden pallet or iron pallet, and the surrounding is

packed with corrugated paper.

7.3. The packaging method of the whole container: 20-23 tons (about

3000 pieces) 20-foot container, 10-12 pallets.